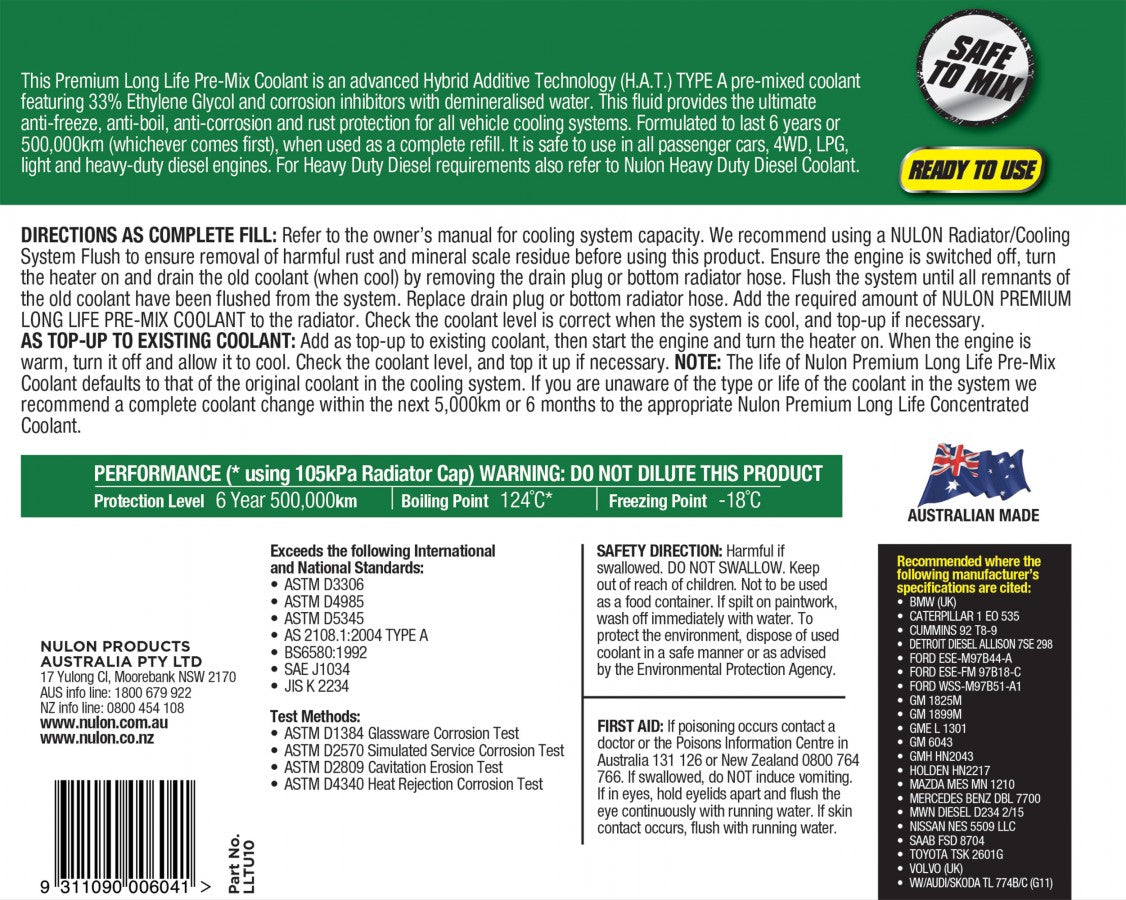

INDUSTRY SPECIFICATIONS

Meets or exceeds the following industry specifications.

| INDUSTRY GROUP |

SPECIFICATIONS |

| AS Claims |

AS 2108-2004 Type A |

| ASTM |

ASTM D1384 |

| Other Claims |

JIS K2234 (Japan) |

| Society of Automotive Engineers (SAE) |

SAE J1034 |

| ASTM |

ASTM D4985 |

| Audi |

Audi G11 |

| Caterpillar |

Caterpillar 1 EO 535 |

| BMW |

BMW (UK) |

| Cummins |

Cummins 92 T8-9 |

| Ford |

ESE M97-B44A |

| Ford |

ESE M97-B18C |

| GM |

GM 1825M |

| GM |

GM 1899M |

| Volvo |

Volvo (UK) |

| Mazda |

Mazda MES MN 1210 |

| Mazda |

Mazda MES MN 121D |

| Holden |

HN 2043 |

| Holden |

HN 2217 |

| Mercedes Benz |

Mercedez Benz DBL 7700 |

| Nissan |

Nissan NES 5059 LLC |

| Other Claims |

FL22 |

| Other Claims |

ETHYLENE-GLYCOL COOLANT 850 |

| Other Claims |

BS 6580:1992 |

| Other Claims |

GME L 1301 |

| Other Claims |

Mopar Formula HOAT (MS-9769) |

| Other Claims |

MWN Diesel D234 2/15 |

| Paraflu |

Paraflu 11 |

| SAAB |

SAAB FSD 8704 |

| Toyota |

Toyota K2601G-1G |

| VW |

VW G11 |

Nulon LLTU is recommended for the protection of cooling systems of all petrol engines and heavy and ligh-duty diesel engines operating in on-road, off-road or stationary conditions. LLTU provides maximum protection against cavitation erosion of wet cylinder liners in diesel engines. Refer to Nulon Fact Sheet No.108 for more information re diesel engine applications. (Note: for maximum protection, particularly in heavy-duty diesel applications, use Long Life Concentrated Coolant (LL) at 50% volume with clean soft or demineralised water).

LLTU is guaranteed to be suitable for the protection of cooling systems of all passenger vehicles where an anti-freeze/anti-boil coolant is specified. Nulon LLTU is also suitable for older vehicles where a broader cooling system operating temperature range is desired, or as a replacement for conventional corrosion inhibitors.

Note: Where a manufacturer specifies Organic Additive Technology (OAT) long life coolant, use either of Nulon's Red Long Life Coolants.

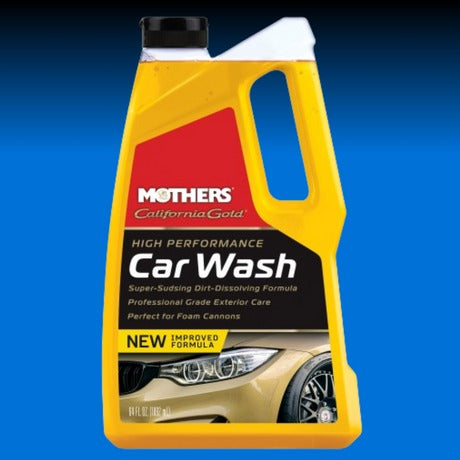

Recommended step-by-step guide for changing coolants

- Before proceeding, read your owner's manual as some vehicles may have special requirements.

- Check that all hose connections are tight. Also check the condition of all hoses, fittings and belts.

- Use Nulon Radiator Flush and Clean (R40) to ensure that the radiator and engine are as clean as possible. This ensures maximum coolant life.

- R40 should be added to the old coolant. With the heater on, run the engine, or drive for 20 minutes minimum, 1 hour maximum.

- Stop the engine and allow it to cool. Remove the bottom radiator hose or drain plug to drain out all the old coolant. It is important to rinse out all traces of old coolant from the engine block and heater circuit. To best achieve this refill the system with clean water - run the engine up to operating temperature and when it is cool drain and flush again. This will ensure a clean environment for the new coolant.

- Check the cooling system capacity of the vehicle and add the required dose of Nulon Concentrated Coolant (do not pre-mix), then fill with soft clean or demineralised water. Any leftover product can be pre-diluted and used as a top-up.

- Some vehicles may require "air bleeding" to remove trapped air from the heater circuit and cylinder head. An air bleeding screw is located on the engine of some vehicles for this purpose. If you are unsure about this procedure please seek further advice before proceeding. Removing the return heater hose from the water pump to establish water flow, whilst topping up, will assist in reducing "air locks". Note: air locks can cause severe engine damage.

- Start the engine and monitor coolant level and temperature until the thermostat opens and the vehicle reaches operating temperature.

- When the vehicle cools down re-check the coolant level.

Note: This check sheet should be used as a guide only. Some vehicles may have special requirements that are not noted above. We strongly advise that you read your owner's manual or relevant workshop manual before proceeding with a coolant change.

| PROPERTY |

NULON LLTU |

| Density (g/ml at 20°C) |

1.053 |

| Freezing point, °C |

-18 |

| Boiling point °C |

105 |

| pH |

7.7 |

| Reserve alkalinity (ml) |

6 |

| Chloride Ion (mg/L) |

<10 |

Foaming: Height (ml)

Break Time (seconds) |

45

2 |

| Shelf life |

3 years |

| Colour |

Green |

| Odour |

Characteristic |

| Glycol content (grams per litre) |

346 |

| Coolant hose test (SAE J20) |

Pass |

Temperature protection chart (using105 kPa radiator cap)

| Boils at |

127°C |

| Freezes at |

-18°C |

Simulated Service Test (ASTM D 2570)

| METAL |

*AS/NZS 2108.1:2004 |

**RESULT FOR

NULON LLTU |

| Copper |

20 |

1 |

| Solder |

60 |

1 |

| Brass |

20 |

2 |

| Steel |

20 |

0 |

| Cast iron |

20 |

1 |

| Aluminium |

60 |

1 |

*Maximum allowed weight loss (mg)

**Actual weight loss (mg) |

Glassware Corrosion Test (ASTM D 1384) S

| METAL |

*AS/NZS 2108.1:2004 |

*ASTM D 3306 |

RESULT FOR NULON LLTU |

| Copper |

10 |

10 |

1 |

| Solder |

15 |

30 |

1 |

| Brass |

10 |

10 |

0 |

| Steel |

10 |

10 |

1 |

| Cast iron |

10 |

10 |

2 |

| Aluminium |

15 |

30 |

1 |

* wt. loss mg (max)

Water Pump Cavitation Erosion Test (ASTM D 2809)

| METAL |

AS/NZS2108.1:2004 (RATING OUT OF 10) |

TYPICAL RESULT FOR NULON LLTU |

| Cast aluminium |

8 minimum |

9 |

Aluminium Heat Rejection Corrosion Test (ASTM D 4340)

| NULON LLTU CORROSION RATE (MG/CM2/WEEK) |

AS/NZS 21008.1:2004 (MAX ALLOWABLE RATE, MG/CM2/WEEK) |

| 0.17 |

1.0 |